MachineBlocks

MachineBlocks are modular, reusable building units designed for zero-waste fabrication. On JandroideTV, they are printed live and used as the structural foundation for real devices and for the simulated MMRF-A01 facility.

What MachineBlocks Are

MachineBlocks are modular physical building blocks based on a standardized grid system. This grid is compatible with widely used construction standards, allowing MachineBlocks to connect to existing modular ecosystems while remaining fully independent.

They are real, physical objects and are used by an active community, primarily for modular construction and for recreating existing sets using reusable printed parts.

Inside the Jandroide Universe, MachineBlocks are treated as a general-purpose structural system rather than a single product.

The Structural Foundation of the Facility

Within the MMRF-A01, MachineBlocks form the structural basis of nearly all devices, housings and technical units.

Blocks can be scaled proportionally, allowing the same construction logic to be used for small enclosures as well as larger structural elements.

This makes the facility internally consistent: everything follows the same modular logic, regardless of size or function.

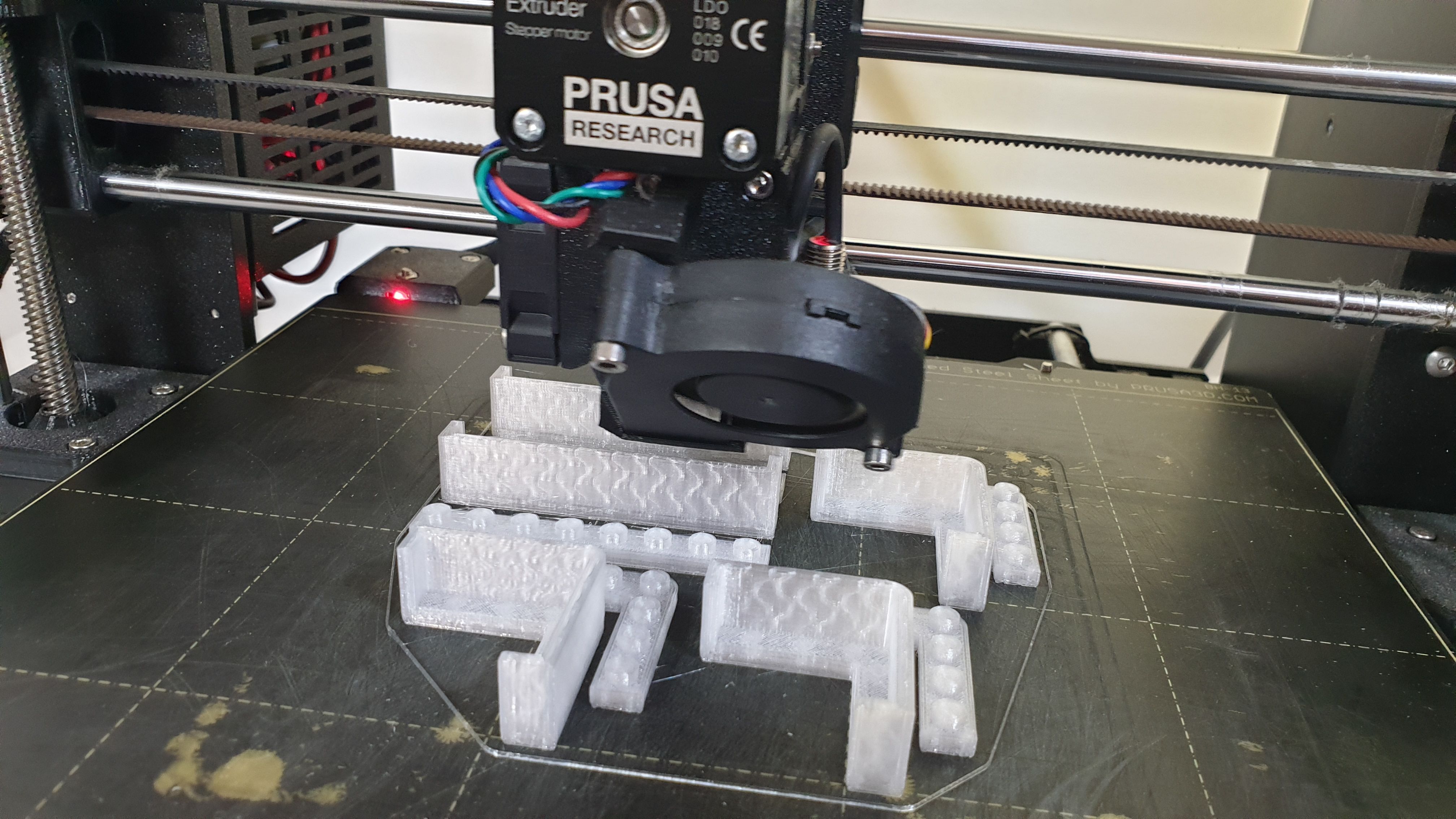

Material and Appearance

MachineBlocks are typically printed in PETG, which offers mechanical stability, durability and long-term reuse.

Inside Martian Micro, MachineBlocks appear semi-transparent and milky white. In reality, this appearance results naturally from printing with transparent PETG filament.

PLA is used only in specific cases, such as compound filaments containing wood or metal particles, where different material properties are required.

3D Printing as a Live Process

MachineBlocks are printed live during the stream. Printing is shown as an ongoing background process rather than a staged demonstration.

Viewers may see printers running continuously, producing parts that will later appear integrated into devices or structures.

A Closed Material Loop

MachineBlocks are designed for a closed material cycle.

Blocks can be disassembled, sorted by material and color, and processed into new filament.

Maintaining material purity is essential to produce consistent filament for future prints.

Filament Recycling as a Mission Goal

At present, filament recycling is a developing part of the system.

Closing the material loop — from printed part back to usable filament — is considered mission-critical for the long-term integrity of the system.

The facility design already accounts for this process, even where real-world hardware is still being integrated.

MachineBlocks Inside the Simulation

Inside the MMRF-A01 simulation, MachineBlocks appear as direct representations of real hardware structures.

They are not decorative props. They represent real parts that exist, are being printed, or will exist.

Watching Continuity Instead of Results

Viewers observe MachineBlocks moving through different roles over time.

A block printed today may later appear in a different form, serving a different function.

The focus is not on completion, but on continuity.